1 a restricted vent pipe 2 too long of vent piping and too many turns which exceeds manufacturer s recommendations 3 a stopped up condensate drain line if you have a high efficiency condensing furnace.

High efficiency furnace pressure switch problems.

If the condensate drain is blocked by debris or frozen condensate or it simply drains improperly the pressure switch may open preventing ignition.

You can disconnect the pressure switch tubing so it will not get damaged and suck the condensate drain line out with a wet vac.

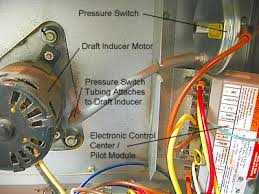

Pressure switch fail open first and most obvious would be failed ventor motor check 110 volts to motor and if it has seized.

The most common problem on high efficient furnaces would be frost or water in the vent.

Some other things that cause furnace pressure switch problems are.

Water in the vent due to a sag in the piping could cause a pressure switch not to close.

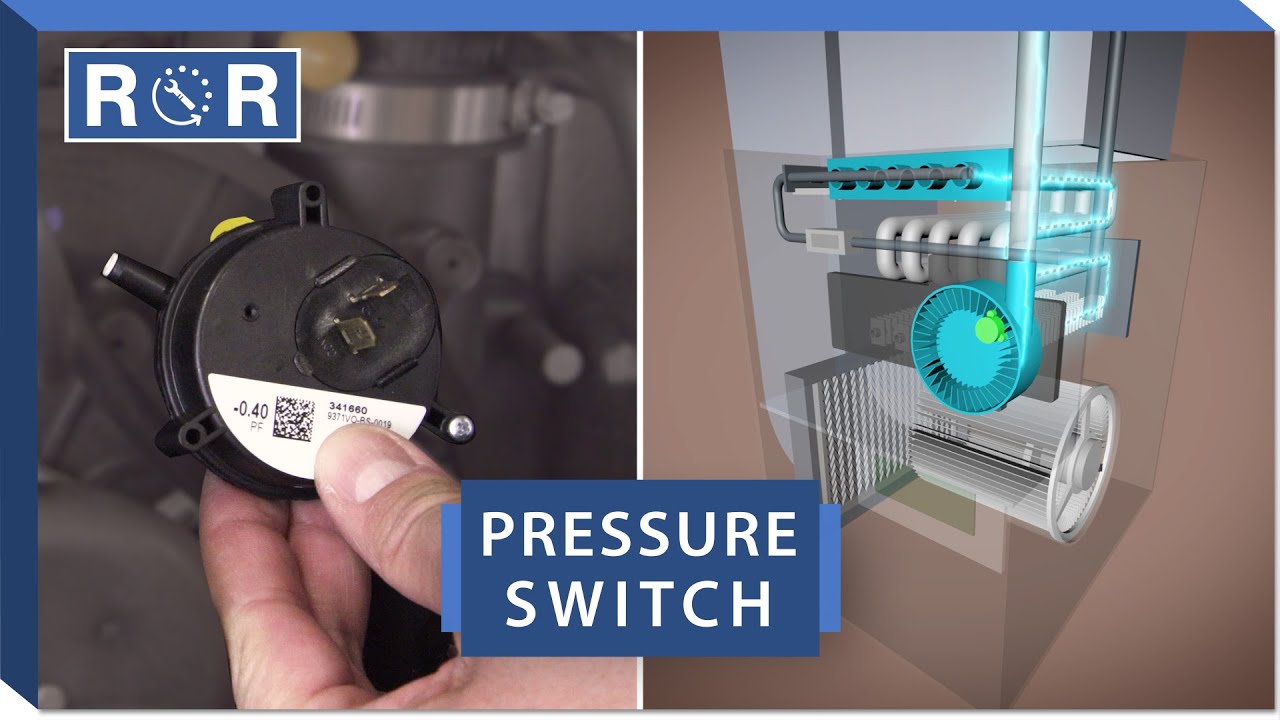

Holes tears or other damage to the diaphragm.

If you have a high efficiency furnace then you probably have a condensate drain and if the condensate drain becomes clogged up it will cause pressure switch problems.

Ice on the venting or a plugged screen on the vent termination only on 90 efficient furnaces could also be the problem.

Problems a furnace pressure switch can develop.

A partially clogged flue vent condensate line or a clog at the condensate collector box near the inducer fan will often trip the furnace s pressure switch.

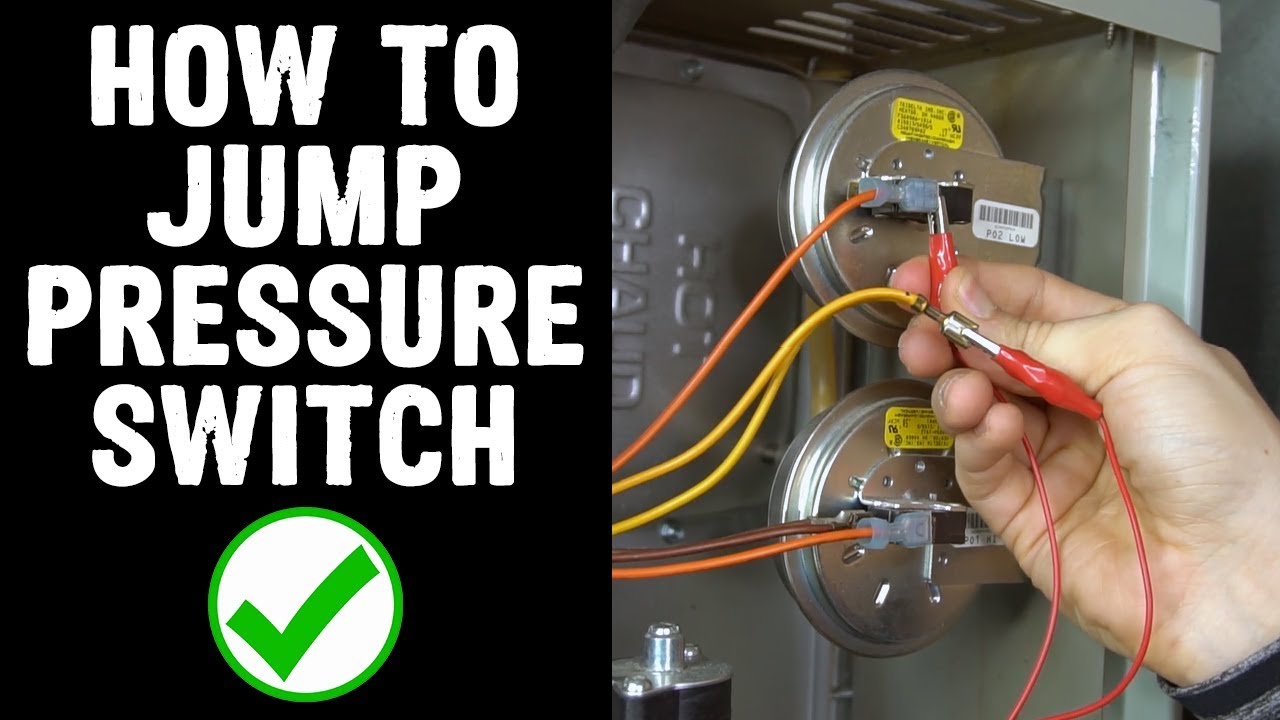

Of course the pressure switch may also shut down if the motor is old and running too slow to satisfy the switch or the hose from the fan to the switch is pinched or broken or the switch itself is bad.

Old age which can cause inaccurate readings and faulty furnace cycling.

If your pressure switch is stuck it is most likely a problem in the running of the furnace.

First off the furnace being high efficient will produce water due to low vent temperatures and condensation in the vent pipe.

4 a dirty or stopped up draft inducer.

Coated or stiffened pressure switch diaphragm.

Pressure switches may act up for several reasons including.

Using a cloth and a wire brush remove any blockages and dirt from the secondary exchanger and the inducer.